HDPE geomembrane with nonwoven geotextile

| Properties | Test Method | Test Value | ||||||

|---|---|---|---|---|---|---|---|---|

| 0.75mm | 1.00mm | 1.50mm | 2.00mm | 2.50mm | 3.00mm | |||

| Thickness - mils (min. ave.) lowest individual of 10 values | D5199 | nom. (mil)-10% | ||||||

| Density (min) | D1505 | 0.940g/cc | ||||||

| Yield strength | 11 kN/m | 15 kN/m | 22 kN/m | 29 kN/m | 37 kN/m | 44 kN/m | ||

| Break strength | D6693 | 20 kN/m | 27 kN/m | 40 kN/m | 53 kN/m | 67 kN/m | 80 kN/m | |

| Elongation at yield | Type IV | 0.12 | ||||||

| Elongation at breaking | 7 | |||||||

| Tearing resistance (min. ave.) | D1004 | 93N | 125N | 187N | 249N | 311N | 374N | |

| Puncture Resistance (min. ave.) | D4833 | 240N | 320N | 480N | 640N | 800N | 960N | |

| Stress Crack Resistance(2) | D5397(App) | 500hr. | ||||||

| Carbon Black Content -% | D4218(3) | 2.0%-3.0% | ||||||

| Carbon Black Dispersion | D5596 | note (4) | ||||||

| Oxidative Induction Time(OIT)(min. ave.) (5) | Standard OIT | D3895 | 100 min | |||||

| High Pressure OIT | D5885 | 400 min | ||||||

| 85°C thermal | Standard OIT | D5721 | 0.55 | |||||

| aging(5),(6)(a) after 90d,OIT retention rate | D3895 | |||||||

| High Pressure OIT | D5885 | 0.8 | ||||||

| UVresistance(7)(a)Ultraviolet radiation 1600h | Standard OIT | D3895 | N.R. (8)50% | |||||

| High Pressure OIT | D5885 |

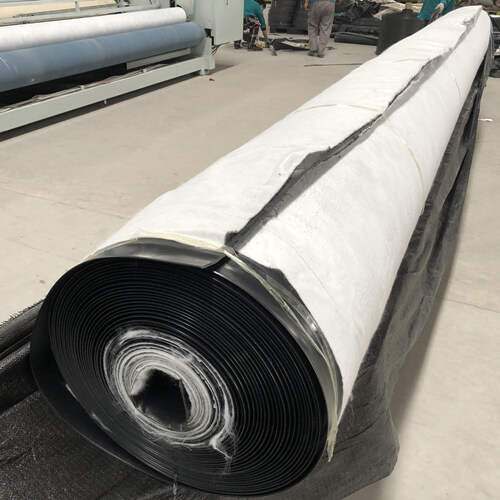

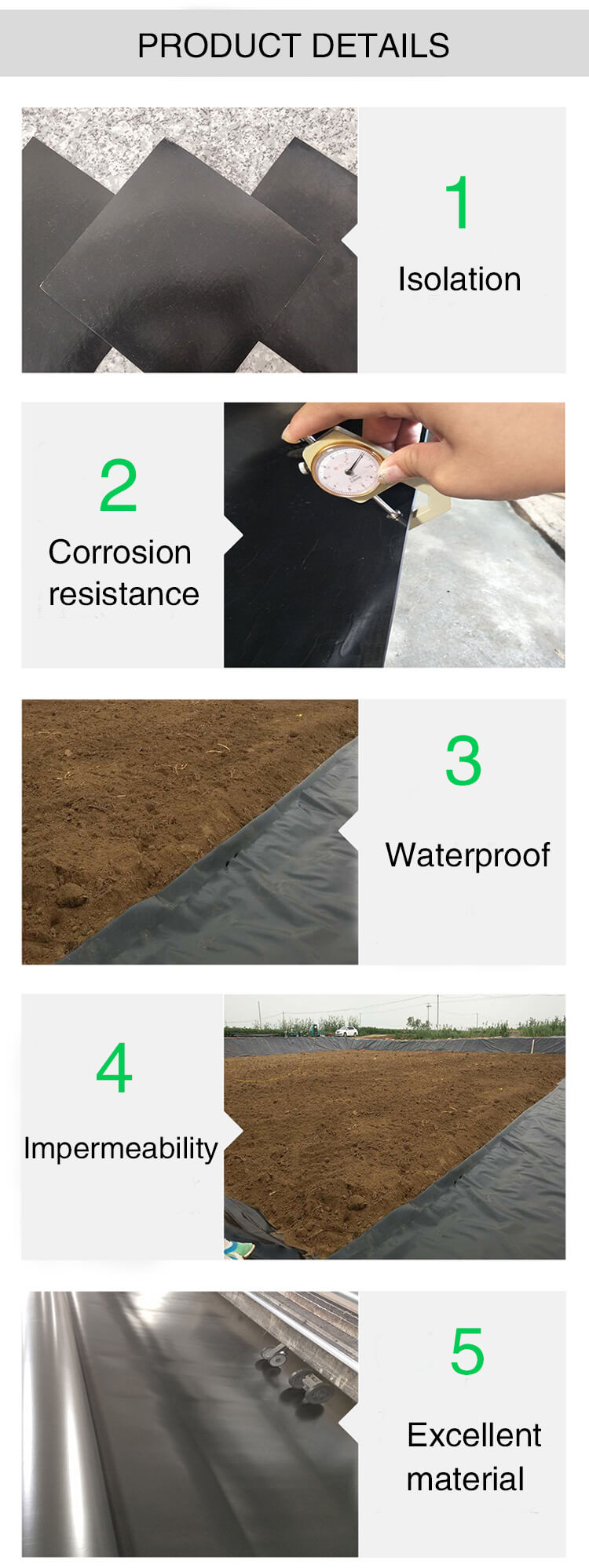

1. High anti-seepage coefficient-HDPE anti-seepage membrane has an anti-seepage effect unmatched by ordinary waterproof materials. The water vapor permeability coefficient K <= 1.0 * 10-13g.cm / c cm2.s.pa.

2. Chemical stability-HDPE impermeable membrane has excellent chemical stability and is widely used in sewage treatment,chemical reaction tanks, and landfills.High and low temperature resistance, resistance to asphalt, oil and tar, acid, alkali,salt and other more than 80 kinds of strong acid and alkali chemical medium corrosion

3. Anti-aging performance-HDPE anti-seepage film has excellent anti-aging, anti-ultraviolet and anti-decomposition ability, can be used naked, the material has long service life, and provides a good material guarantee for environmental anti-seepage.

4. Anti-plant root system-HDPE impermeable membrane has excellent puncture resistance and can resist most plant root systems.

5. High mechanical strength-HDPE impermeable membrane has good mechanical strength, excellent elasticity and deformation ability making it very suitable for expansion or contraction of the base surface, which can effectively overcome the uneven settlement of the base surface.

6. Good economic benefits-HDPE anti-seepage membrane adopts new technology to improve the anti-seepage effect. Not only is the production process more scientific and fast, but the product cost is lower than traditional waterproof materials.

7. Fast construction speed-HDPE impermeable membrane has high flexibility. There are various specifications and various laying forms to meet the impervious requirements of different projects. Hot-melt welding is adopted. The weld strength is high and the construction is convenient and fast.

8. Environmental protection–HDPE impermeable membranes are all new raw materials. The principle of impermeability is ordinary physical changes, which will not produce harmful substances. It is a good choice for environmental protection, breeding, and drinking water tanks.